Sustainability

A Circular

Approach

Circularity

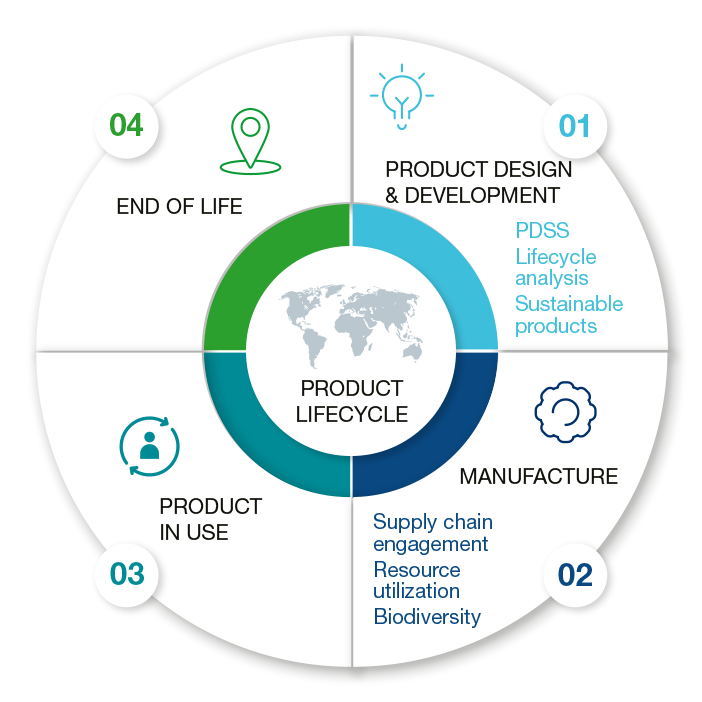

With finite planetary resources, circularity is essential. Working closely with customers in sectors like wind energy and boatbuilding, we aim to advance fully circular products. Gurit is committed to considering circularity and decarbonization at all stages of a product’s lifecycle, from product development through to end-of-life.

Cleantech

As a pioneer in composite technology, Gurit uses its technical expertise to reduce both our footprint and that of our customers. We leverage innovation to lower emissions, optimize resources, and contribute to recycling and circularity. Industry partnerships help us focus our efforts on areas where we can use our technical know-how to make the biggest sustainability impact.

1. Product design & development

Gurit integrates safety and sustainability at every product lifecycle stage, from raw material selection to end-of-life. PDSS (Product Design for Safety and Sustainability) principles guide product development using established frameworks and data-driven decisions.

LCA helps Gurit track and reduce environmental impact from conception to disposal. Internal analysis drives improvements based on various impact factors.

Gurit develops safer, bio-based formulated products with lower carbon footprints. We offer natural fibers and produce PET foam with up to 100% recycled content. Our PET production waste is also recycled into new foam core material.

2. Manufacture

Through ESG risk assessments and due diligence, Gurit ensures ethical sourcing, addressing issues like child labor and conflict minerals. We work with suppliers to track emissions and improve data accuracy for reduction efforts.

We optimize energy use, support cleaner electricity, and implement water efficiency strategies. Waste reduction is achieved through resource efficiency, re-use, and recycling.

Aligned with SDGs 14 and 15, we prioritize biodiversity and ecosystem health across operations.

3. Product in use

Gurit enhances customer efficiency with low-temperature, fast-curing prepregs and resins, as well as automated tooling for large parts to shorten cycle times. Composite materials enable electrification and fuel reduction through strength and low weight, while resisting moisture and rot, extending lifespan.

We also prioritize product safety by working to eliminate high-hazard chemicals and SVHCs.

4. End of Life

Recycling is complex as composite structures are inherently durable, mixed material structures. Gurit contributes to EU-based research consortia to develop closed-loop recyclable technology by 2026.

To read about our Environmental progress, please read the latest Sustainability Report: