GURIT® KERDYN™

RECYCLED THERMOPLASTIC CORE

- Gurit® Kerdyn™: up to 100% recycled PET based product range

- Withstands high process temperatures

- Excellent chemical resistance

- Good adhesion & mechanical properties

- Recyclable

- PET low resin uptake performance

Highly adaptable, recyclable, thermoplastic core material with good balance of mechanical properties, temperature resistance, density and cost for a wide range of applications and processes. Gurit® Kerdyn™ is compatible with a wide range of resin systems including epoxy, vinyl ester, unsaturated polyester and phenolic resins.

Typical Applications

Gurit® Kerdyn™ can be processed at high temperatures, withstanding high exotherms and offers outstanding chemical resistance, good adhesion; as highly consistent extruded foam, it is ideal for wind energy, marine, industrial, and transportation applications.

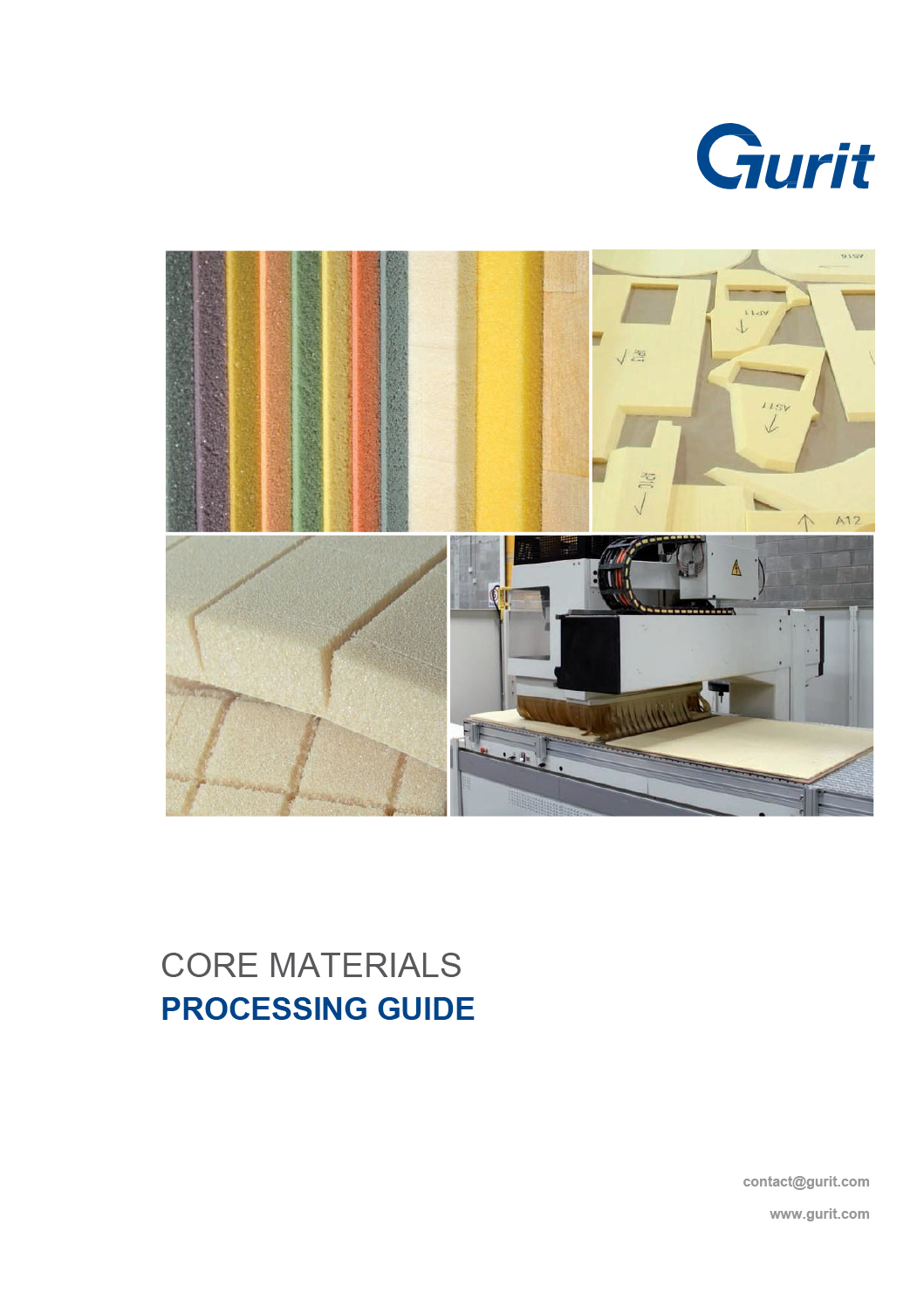

Applicable processing techniques include vacuum infusion, bonding, prepreg, and thermoforming.

Available in a wide range of densities and thicknesses.

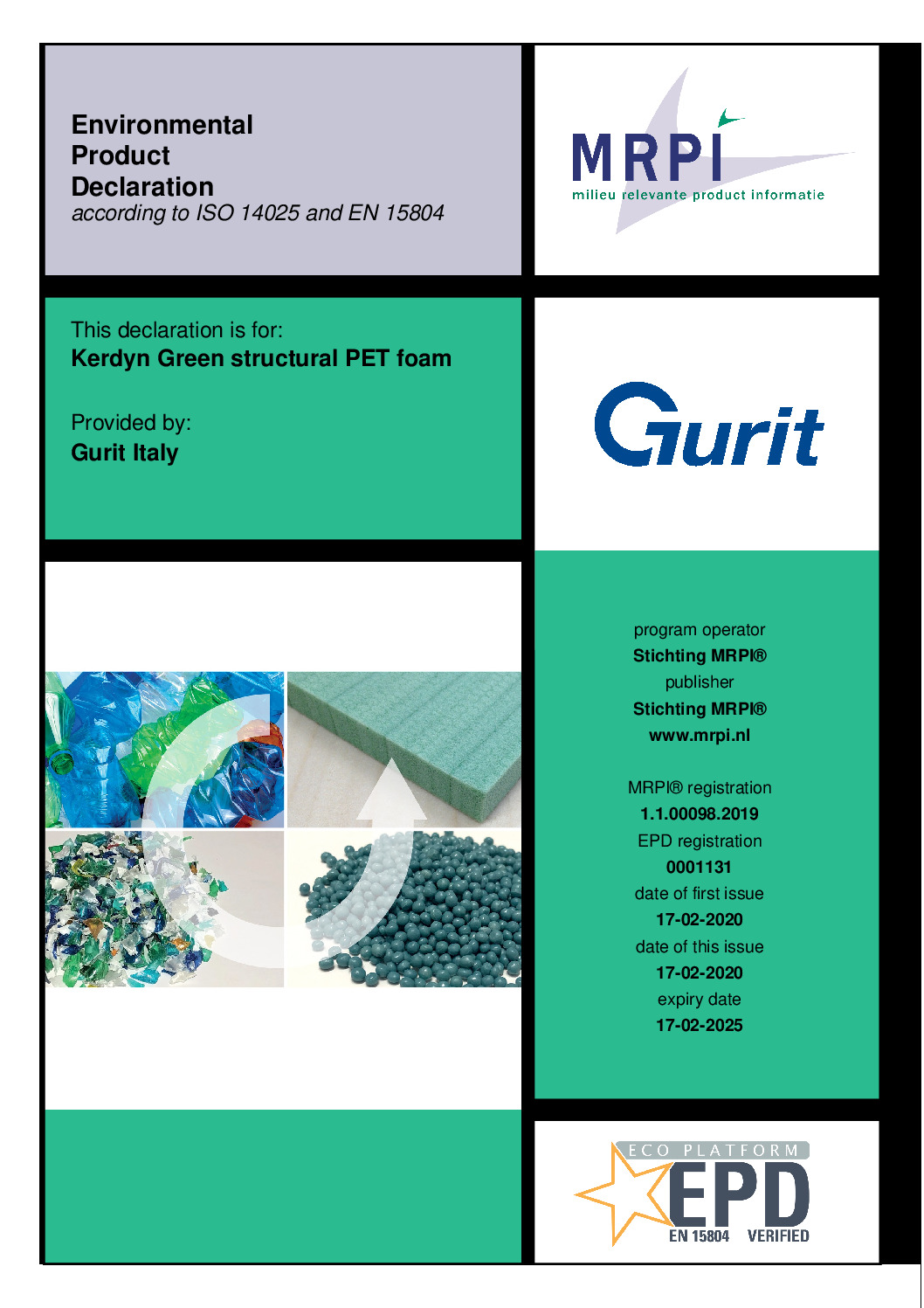

Up to 100 % recycled PET based structural foam

A VALUE CHAIN FOR RECYCLED POST-CONSUMER WASTE

Gurit recycles post-consumer waste PET bottles and produces recycled PET flakes and granules later used for extrusion of recycled PET core. This allows us to secure quality and cost-effective raw material supplies for PET composite production, and link the value chain elements starting from the recycled bottle down to a finished quality core material, Kerdyn™.

In 2023, Gurit recycled

million post-consumer PET drinking bottles

In 2023 Gurit recycled

tons of PET waste generated through our own operations

Recycled PET Panels for Lightweight Construction

Meet Gurit Kerdyn™ – your perfect match for a sustainable product life cycle

- Reduced weight, whilst retaining sustainability

- Sustainable: a recycled and recyclable panel structure

- Good insulation properties

CASE STUDIES

Case Study

Lemker & Harris

Lemker & Harris is the leading manufacturer of mobile fiberglass radiographic testing darkrooms for the non destructive testing service and inspection industry in the USA, in operation since 1975.